Despite the perturbations that have undermined the construction of an onshore section of the Baltic Pipe in Denmark, the expansion of the Norwegian Corridor continues. The construction of the so-called tie-in to the Europipe II gas pipeline under the North Sea is one of the most advanced sections of the entire project – Mariusz Marszałkowski, editor at BiznesAlert.pl, writes.

The tie-in construction continues

The Europipe II gas pipeline was constructed at the end of the previous century. The pipe is 658 km long and runs from a gas processing facility in Norway’s Kårstø to a gas compressor station in Germany’s Dornum. It was commissioned on the 1st of October 1999. A single line of the gas pipeline has a 42 inch diameter (1100 mm) and is capable of transmitting 24 bcm of gas a year. The gas extracted in the Norwegian shelf will be transported via this pipe, and then through the new sections of the Norwegian Corridor via Denmark and the Baltic Sea to Poland.

The tie-in is a 105 km long connection between the Danish beach Houstrup and the Europipe II, which was very quickly assembled by two vessels owned by the Swiss-Dutch Allseas company – Tog Mor, which worked on the 4th km of the shelf section, and the biggest pipe-laying vessel in the world that handles underwater gas pipes – Pioneering Spirit. However, completing the pipe laying does not mean the tie-in is ready. Currently a different Allseas ship, Lorelay, is working on the completed section to perform post-pipeline laying activities. It uses a special mechanical trenching machine called Digging Donald to bury the pipes under the seabed. Previously the machine was installed on the Calamity Jane vessel, but last year the ship was withdrawn from the Allseas fleet.

However, the most important task that is yet to be done, is to physically connect the Europipe II with the tie-in.

During the construction of the Europipe II the designers made it possible to add an extra manifold to make it possible to transmit Norwegian gas to Denmark. Thanks to this decision, today it is possible to talk about the Baltic Pipe project without the necessity to build a new gas pipeline from Denmark to Norway.

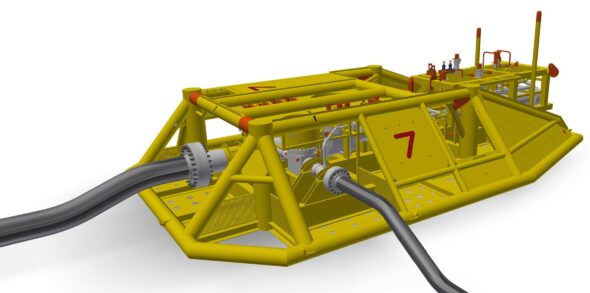

The tie-in can be connected thanks to installing a Pipeline End Manifold (PLEM), which will join the two gas pipelines.

PLEM makes it possible to connect the tie-in to the existing Europipe II gas pipeline. It includes valves and a manifold, which are placed under a metal skeleton. PLEM is put in the place where the tie-in has been already laid. Connecting the two requires impeccable precision, which is why it is done by deep water divers. Some of the installation, including assembling pipes inside the PLEM, is done onshore. Then a special vessel is used to transport the device to its undersea destination. In case of this tie-in the connection will be assembled about 40 meters below the water surface.

The PLEM is quite big. It weighs over 215 tons, is 19 meters long and 12.5 meters wide, and 3.5 meters high. It can inject special inspection pistons into the gas pipeline, which monitor its technical condition and perform maintenance from within. Additionally, thanks to the valves, it is possible to cut off the gas supply to the tie-in, in case there is, e.g. a breakdown during maintenance works, without the necessity to stop gas transit from Norway to Germany.

The contract for constructing the manifold was won by Subsea 7, a company registered in Luxemburg. It was signed on the 10th of July 2019 with Equinor, which is responsible for the technical supervision of the Europipe II gas pipeline. Wheras the pipe’s operator is the state-owned Norwegian Gassco. The PLEM is being built in a Norwegian shipyard, the deadline is the beginning of the third quarter of 2021.

The manifold will be transported in the early summer, probably by the Seven Falcon, the biggest offshore supply vessel owned by Subsea 7. The ship is equipped with a 250 ton crane, which will be used to place the PLEM on the North Sea seabed. The process of placing the PLEM and stabilizing it by rock placement will take until Spring 2022. Thanks to the fact that the contract had been signed already in 2019, the process should not be delayed, despite the fact that the coronavirus pandemic did impact the work of the factories involved in the production of components needed to assemble the manifold. One of the manufacturers that was struggling because of the pandemic was an Italian company that produces special sliders used in gas pipelines.

Despite the difficulties in Denmark, the offshore part of the pipe, at least for now, is going according to plan. We should remember that in the majority of gas pipeline projects, delays are usually caused by the offshore part, because of its characteristics and the unpredictability of working at sea.