During a Senate session, Piotr Naimski, the Government Plenipotentiary for Strategic Energy Infrastrcuture, stated that the offshore construction of the Baltic Pipe gas pipeline may end already this year, and the first ship that is being prepared to build the pipe is to set out to the Baltic Sea from Rotterdam on the 5th of May. What will the coming months at the Baltic Pipe construction site look like? – asks Mariusz Marszałkowski, editor at BiznesAlert.pl.

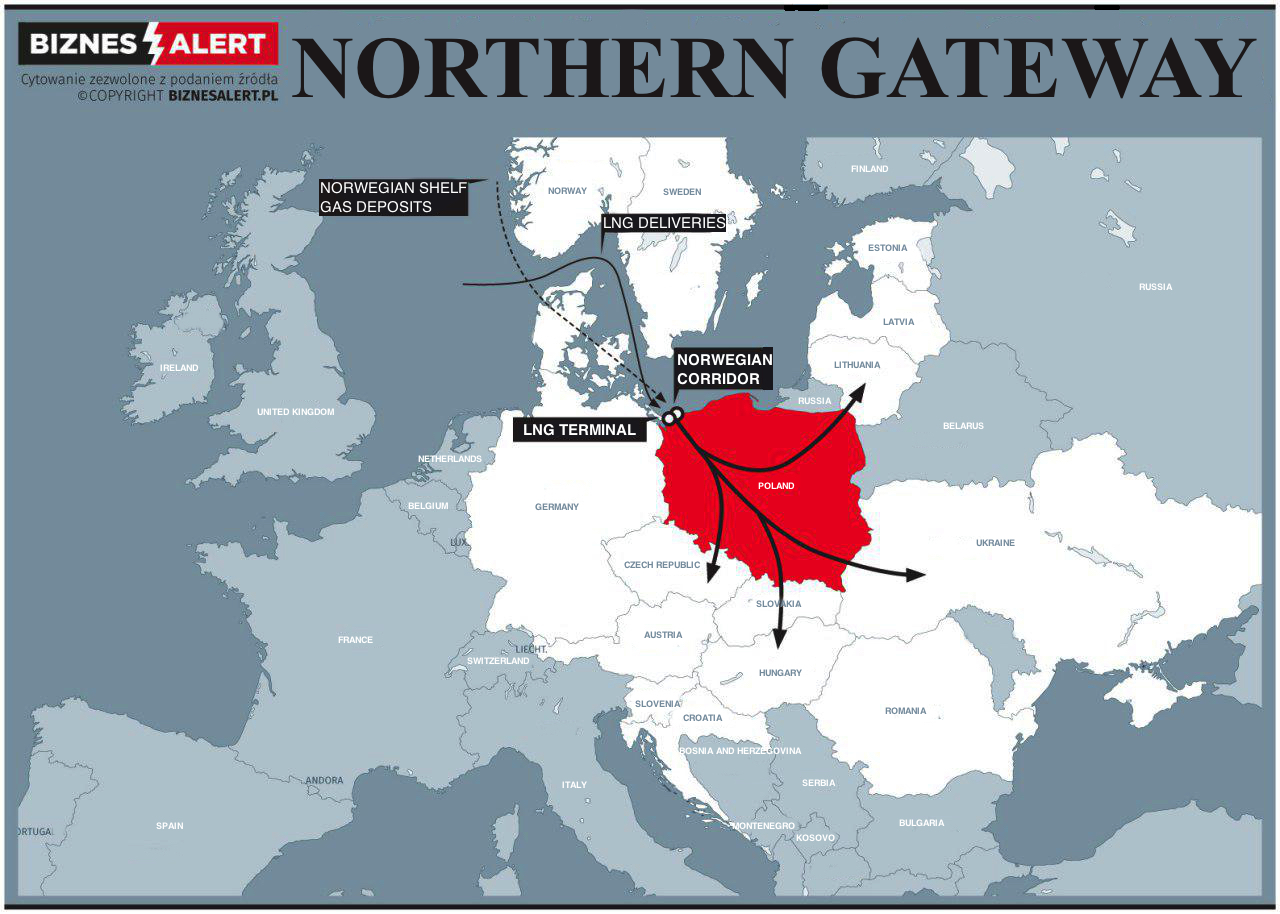

The construction of one of the biggest gas supply diversification projects in Poland’s history is fast approaching. I will not dive into the history of the project, or why it is so important. In this article I will describe what will happen in the near future in the context of the construction process of one of the elements of the so-called Northern Gateway.

Construction stages

The Baltic Pipe will be an underwater, 36-inches in diamater (ca. 900 mm), Baltic gas pipeline 273 kilometers long, which crosses the territorial waters and exclusive economic zones (EEZ) of three states:

Denmark – about 132 km in length (territorial and EEZ waters)

Sweden – about 85 km (EEZ waters)

Poland – about 56 km (territorial and EEZ waters).

The construction of the gas pipeline is not just about laying the pipes. The process is preceded and followed by a number of other actions, which the contractor needs to take. They are divided into the following categories:

1. Pre-lay construction activities

2. Pipeline installation

3. As-Laid survey

4. Post-lay seabed intervention

5. As-Built survey

Activities from the first category involve:

– removing obstacles from the route of the pipe (e.g. boulders),

– removing unexploded ordnance (UXO),

– exploring the seabed,

-placement of concrete “mattresses” on installations, which will cross with the gas pipeline.

The second category involves:

– laying the gas pipeline at the seabed, and touchdown monitoring.

The third category involves:

– assessing whether the pipes were laid correctly at the seabed and are stable.

Activities from the fourth category involve:

– rock placement (to stabilize the pipeline, cover the crossings with other underwater installations),

– burying the gas pipeline in the seabed, e.g. in anchorage areas, or port approaches, etc.

The fifth category involves:

– assessing the correctness of the work carried out to, among others, certify the pipe and authorize it for use.

Constructing the Baltic Pipe

In case of the Baltic Pipe some of the activities are already in process, while others are about to start. The relevant authorities responsible for regulating the activities in Denmark’s and Sweden’s waters have already published the required navigational warnings. Currently pre-lay construction activities are either already taking place, or will shortly start at every section of the pipe. The ETD Hercules vessel is currently working in Poland’s EEZ. The ship, among others, monitors for UXO and if necessary removes the “obstacles” from the seabed. NG Worker and TSM Ouessant are doing similar work in Denmark’s territorial waters. According to the navigational warning issued by the Danish Maritime Agency, the works will last until the end of May. The warning also says that all of the construction in the Danish section will end in January 2022.

In Sweden’s EEZ the UXO will be either removed or detonated between 1 and 31 May. Also, between 1 May and 30 June concrete mattresses will be placed on top of installations that the Baltic Pipe will cross. According to a report by Espoo, 26 mattresses will have to be installed along the gas pipeline – 22 will be on top of cable connections and 4 on pipeline connections (Nord Stream 1 and 2).

The pipe-laying is to start in June. According to the navigational warning issued by the Swedish maritime administration, the works in Sweden’s EEZ are to start on 20 June and will end on 30 July.

The pipe-laying work will be done by the Castorone, a dynamically positioned vessel, owned by the main contractor responsible for the project – Saipem Limited. Dynamically positioned vessels will work on sections where the depth is over 20 meters. The depth of the Swedish section is between 32 and 50 meters. In the sections where the depth is less than 20 meters, anchored vessels will lay the pipes. They will be mostly used in the territorial waters of Poland and Denmark.

The Danish Maritime Agency says that in its area of responsibility the work will be performed by Castorone and two anchored vessels – Castoro Sei and Castoro 10. Both vessels built the Nord Stream gas pipelines (Castoro Sei – Nord Stream, Castoro 10 – Nord Stream and Nord Stream 2).

According to the schedule, pipe laying will take up to four months. After that, post-pipeline laying activities will take place, the majority of which will involve burying the pipeline in the seabed and rock placement. The plan is that the gas pipeline will be buried in areas where the depth is less than 20 meters. Two methods will be used to perform this work. In the shallow shelf waters (up to 12 meters) the work will be done by cutter suction dredgers or trailer suction hopper dredgers. In deeper waters a special underwater plough will be used. It will move along the pipeline and bury it in the seabed.

In places where it will be impossible to use the plough (e.g. due to the kind of the seabed, or environmental requirements) or other suction dredgers, a mechanical digging will be used. The method works similarly to the plough, but it can be used in areas where the bottom is made of, e.g. rocks. It is significantly slower than the other methods. It is estimated that in case of the Polish section, 3 km will have to be dug out mechanically. In places where it won’t be necessary to bury the pipeline, it will be possible to alternatively use rock placement.

Initial project estimates state that the gas pipeline will be buried in the seabed at a length of 125 km. This may change, because the seabed research is still in progress.

According to the documents submitted as part of the consultation procedure, the volume of material removed during the digging is:

In Denmark – 720 140 cubic meters

In Sweden – 236 600 cm

In Poland – 439 500 cm

The blue points on the map on the Baltic Pipe route show where the mattresses will be placed, whereas the red lines show sections where the pipe needs to be put under the seabed, or rock placement should be performed.

The fleet that is building the Baltic Pipe will have at least 20 ships and barges at its disposal at different stages of the process. At this point it is possible to identify 15 of them on the basis of navigational warnings:

Pipe Laying Vessels (PLV)

Castorone

Castoro Sei

Castoro 10

Offshore Supply Ships (OSV)

Ievoli Ivory

Ievoli Amber

Vessels handling the UXO and removing obstacles from the Baltic Pipeline’s route.

Noordhoek Pathfinder

Noortruck

TSM Ouessant

ETD Hercules

NG Worker

Dredgers

MJØLNER R

Heimdal R

GUNGNER R

Harald

TOSTE R

The other ships that are part of the fleet are pipe supply vessels (PSV), anchor handling tug vessels, pipe burying vessels (PBV), GUARD vessels, as well as other ships that participate in the construction.

The pipe laying vessels will be surrounded by an exclusion zone, where sailing and other maritime activities will be forbidden. Its radius will be 1500 meters. During the works in the TSS zone (Traffic Separation Scheme) by the Bornholmsgat (strait between Bornholm and Sweden), the exclusion zone’s radius will be 1000 meters wide. Around all the other vessels engaged in the construction of the Baltic Pipe a safety zone with a 500 meter radius will be established. Along the laid pipeline a 200-meter corridor will be set up, which will be excluded from maritime activities (ban on fishing, diving, anchoring).

Logistics behind the Baltic Pipe

Logistics is the key element that will allow the construction of the Baltic Pipe to go smoothly. This pertains to the supply chain of equipment, supplies, vessels and pipes. The main contractor is responsible for these tasks, and has the leeway to decide how to organize them.

Ensuring the supply of pipes, which are put on the seabed, is one of the most crucial issues. Gaz-System claims that the Baltic Pipe is to be constructed at an average speed of 3 km a day, which means the pipe laying vessels need to receive at least 240 pipes, each 12.2 m long, every 24 hours.

According to brockerage data, since mid March Saipem has been looking for a timely charter of at least 6 pipe supply vessels (that provide pipes, as well as other necessities, such as fuel, lubricants or food).

These units will regularly travel between the logistics harbor and the pipe laying vessels.

Sweden’s maritime administration documents say that the German port in Mukran will be the logistics harbor for the Baltic Pipe.

The port is currently the main logistics port for the Nord Stream 2 project. It looks like the PSVs that supply Nord Stream 2 will, for some time, pass ships that will carry the pipes and supplies to the vessels that take part in the construction of the Baltic Pipe. According to an Espoo report on the pipe, 23,155 pipes will be used to build the pipe (over 130 thousand tons), and their total storage area is about 86 sq km. The Portal Morski website did an in-depth analysis on the choice of Mukran as the logistics port.

Commissioning and testing the Baltic Pipe

Construction of underwater pipelines is a complicated operation in many areas. At this point it has not been revealed to the public yet what vessels will lay pipes in the individual sections of the pipeline. Considering how the vessels were used in the past, one can expect that the Castoro 10 will operate on the shallowest sections of the investment (from the shore to the sea). Castoro Sei will probably lay pipes in sections that are 12-20 meters deep, and in areas where anchored vessels need to be used. Whereas Castorone, as Saipem’s most efficient pipe laying vessel, will probably work in areas where the water is deeper than 20 meters, especially in the TSS Bornholmsgat where the traffic is so dense that the works need to be completed as quickly as possible.

It is also unclear whether the 20 of June is the day when the works will start only in the Swedish zone, or a general deadline for starting the pipe laying.

Once the pipes are down, stabilized and inspected, the so-called pre-commissioning will take place. As part of that phase, the pipeline will be filled with water. In order to make sure the pipes do not corrode on the inside, oxygen scavengers are added, e.g. sodium bisulfite. According to calculations made by Ramboll in 2018, in order to fill in the Baltic Pipe with water, it will be necessary to use 20 tons of sodium bisulfite. The water (deprived of oxygen) will be discharged back into the sea via discharge lines near the Faxe Bugt landfall in Denmark.

Once the pipe is filled with water, the so-called intelligent calliper is put into the pipe, which verifies the pipe’s diameter and monitors the quality of welding. The goal of this test is to discover any errors and problems related to the quality of the welding. Apart from the intelligent calliper, brush and foam pistons are propelled through the pipe to clean it. To make the cleaning easier, a special cleaning gel, which is collected by subsequent pistons is also added. There will be 5 pistons in the pipe in total, each with a different job. As much as 720 cubic meters of gel will be needed to clean the entire pipe. The pistons are propelled by the water that is injected into the pipe.Once the pipe is cleaned and its state verified by the intelligent calliper, it is dried. Three methods can be used for drying, they usually take place one after another.

The first one is called MEG conditioning (monoethylene glycol). The gel that includes MEG is squirted between the pistons, that are propelled by pressured air and move along the interior of the pipe. The water is absorbed by the gel, and the gel is released outside via pistons. Once the pistons are removed, the pipe is dried with dry air. At the last stage vacuum drying is performed, where the boiling point of water is lowered at low pressure. In order to do this, special vacuum pumps are connected to the pipeline, which after a few days’ work will lower the pressure inside the pipe to a few millibars. Once dried, the pipeline is filled with, e.g. nitrogen, to make sure it does not corrode until natural gas is pumped in.

Will the Baltic Pipe be completed on time?

At this point there are no threats that could undermine the completion of the Baltic Pipe on time. Thanks to Saipem’s fleet and the work schedule, which is mostly around the summer when there usually aren’t any violent storms, the pipes should be laid by mid-September. After that the post-lay seabed intervention will take place.

All the activities in the Danish zone should be finished by the end of January 2022, and by the end of April 2022 the Swedish section should be completed. If this goes according to schedule, the project will still have six months to conduct pressure tests, inspections, certification and gas pumping procedures.

PL

PL EN

EN